Vibro compaction is a ground improvement technique that densifies clean, cohesionless granular soils with a downhole vibrator. It’s a technique first developed by Keller in the 1930s that we’ve used on thousands of projects since.

Common uses

Process

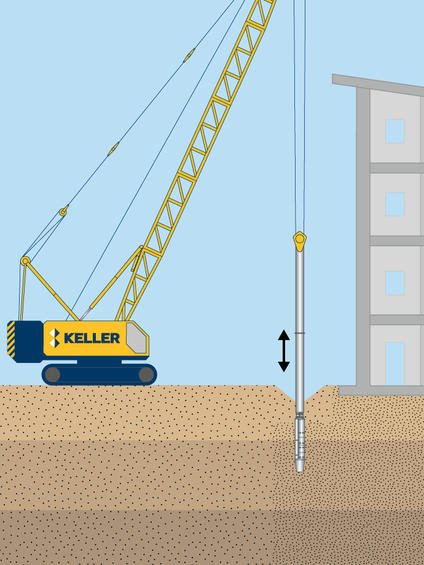

A vibrator hung from a crane is lowered into the ground with penetration usually helped by water jetting. The energy from the vibration reduces the inter-granular forces between the soil particles, making them denser as the vibrator is raised in lifts. Sand backfill is then poured in from ground level to compensate for any decrease in soil volumes. More backfill is added and compacted and the vibrator is gradually removed until it has built up to ground level.

The required treatment depth is designed for each project and is typically in the range of 5m to 20m with depths in excess of 40m possible.

Vibro rigs can be fully instrumented with an on-board data acquisition system. Data from the system, such as amperage and lift rate, can then be recorded and displayed in real-time alongside specified target values on an in-cab monitor. This monitoring allows the operator to correct any deviations in real-time during the construction process to keep the vibro compaction within project specifications.

Advantages

Quality assurance

The vibro equipment we use is designed and manufactured by our in-house equipment manufacturer exclusively for use by Keller companies.

In-house quality production manager software enables us to capture and analyse data in real time and validate the performance of the ground improvement being carried out.

A variety of production parameters are generally logged during execution including depth, current, pull down force, uplift/pull down sequence, time and date and element number.

Field trials can also be used to verify column production parameters, along with static load tests, single or group, column material compressive strength tests, and column diameter verification.